In the design and maintenance of localized mechanical suction systems, the exhaust hood plays a crucial role in capturing and channeling pollutants. What does this term actually mean? By hood, we refer to a device through which air is drawn into a ventilation system to intercept pollutants. Careful design is essential to ensure these pollutants are effectively captured and that the system operates optimally.

There are three main types of hoods:

1. Closed Hoods: Used in confined areas, providing maximum protection.

2. Receiving Hoods: Designed to capture pollutants generated by open sources.

3. Capture Hoods: Ideal for intercepting pollutants in larger or non-confined spaces.

A decisive factor is the capture velocity (V), expressed in meters per second (m/s). This is the air velocity required to counteract internal air currents and ensure pollutants are forced into the hood. This value varies depending on operating conditions and how the pollutant to be removed is generated.

• Lower Velocity Values: Recommended in environments with minimal air currents or conditions that facilitate pollutant capture when dealing with less toxic pollutants, intermittent operations, or large hoods moving large volumes of air.

• Higher Velocity Values: Necessary in the presence of significant air currents, highly toxic pollutants, continuous processes, or smaller hoods requiring higher suction force to effectively capture pollutants.

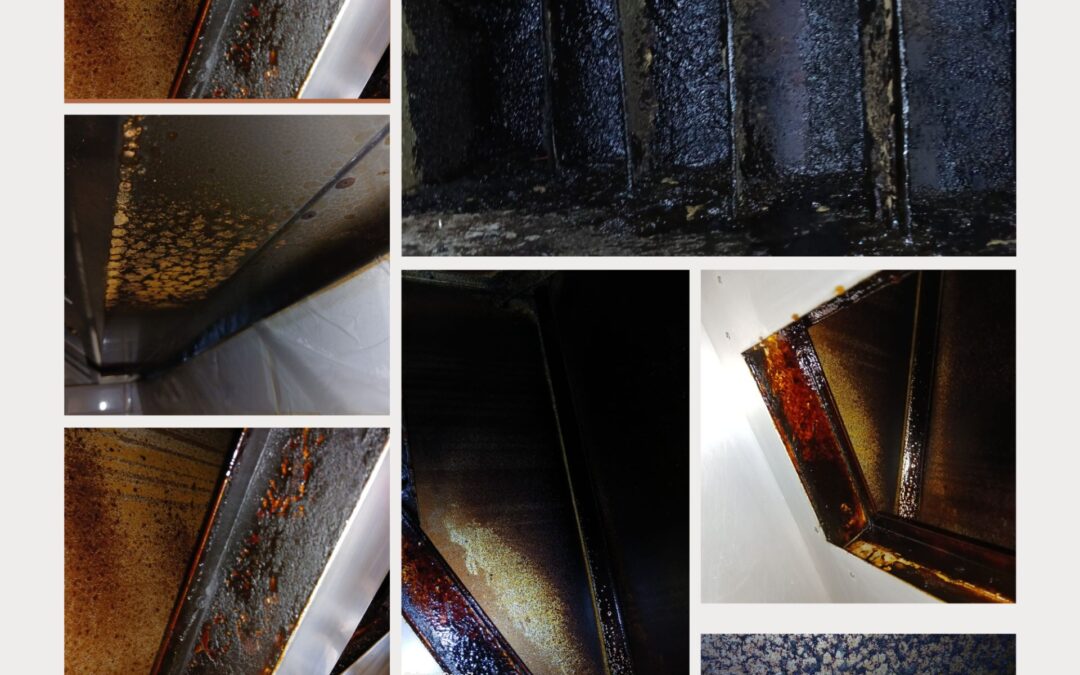

At Vesta Solutions Sagl, we specialize in the remediation and sanitization of air-handling systems, ensuring clean and safe air in every workplace. Our expertise and attention to detail guarantee that every component—from the hood to the entire ventilation system—operates at its best. Air quality is essential for well-being and productivity: discover how we can help keep your systems at peak efficiency!